With automobile production having effectively ground to a halt around the world, the Ford Motor Company’s U.S. operation has teamed up with manufacturing giants 3M and GE to make ventilators for coronavirus patients and face shields to protect the medical workers caring for sick people.

Other automakers are also pitching in, including GM producing 200,000 ventilators and FCA with one million face masks.

The move comes after governments in North America and Europe began urging automakers to pivot toward the production of much-needed healthcare items as the coronavirus and its resulting COVID-19 illness continues to spread. Ventilators are critical to caring for COVID-19 sufferers, as difficulty breathing is one of the main symptoms in severe cases of the illness.

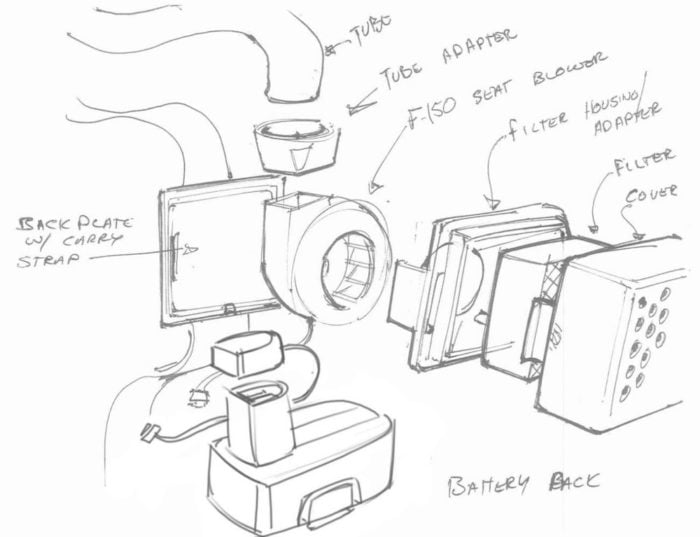

Ford and the UAW are working with 3M to expand production of that company’s powered air-purifying respirator (PAPR), a device that can be used to help ease breathing problems for COVID-19 patients. The collaboration could see respirators made from components as disparate as seat cooling fans from the Ford F-150 pickup truck, 3M’s HEPA air filters, and rechargeable portable tool batteries. A respirator using those parts could run for up to eight hours on a fully charged battery.

Ford says that it could boost production of the devices tenfold by assembling the respirators in one of its Michigan factories.

In another collaborative effort, Ford says it is working with GE Healthcare to expand production of that company’s medical ventilator design.

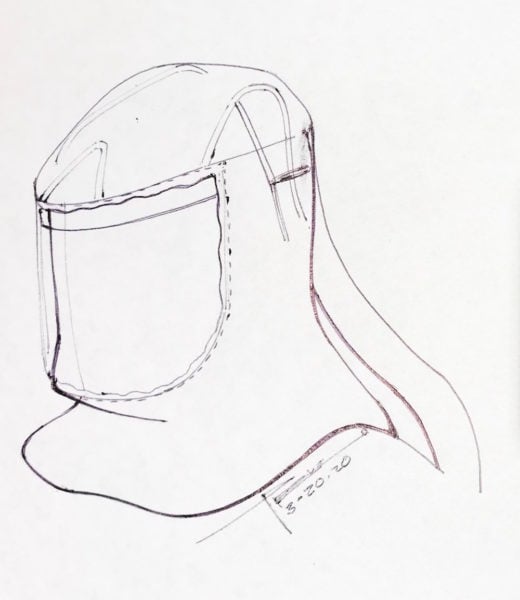

Meanwhile, this week, medical professionals in three Detroit healthcare facilities will start testing a new Ford-designed face shield being produced at a number of its Michigan factories. These full-face shields protect hospital workers and first responders from airborne exposure to the coronavirus.